Corigin’s Value Creation

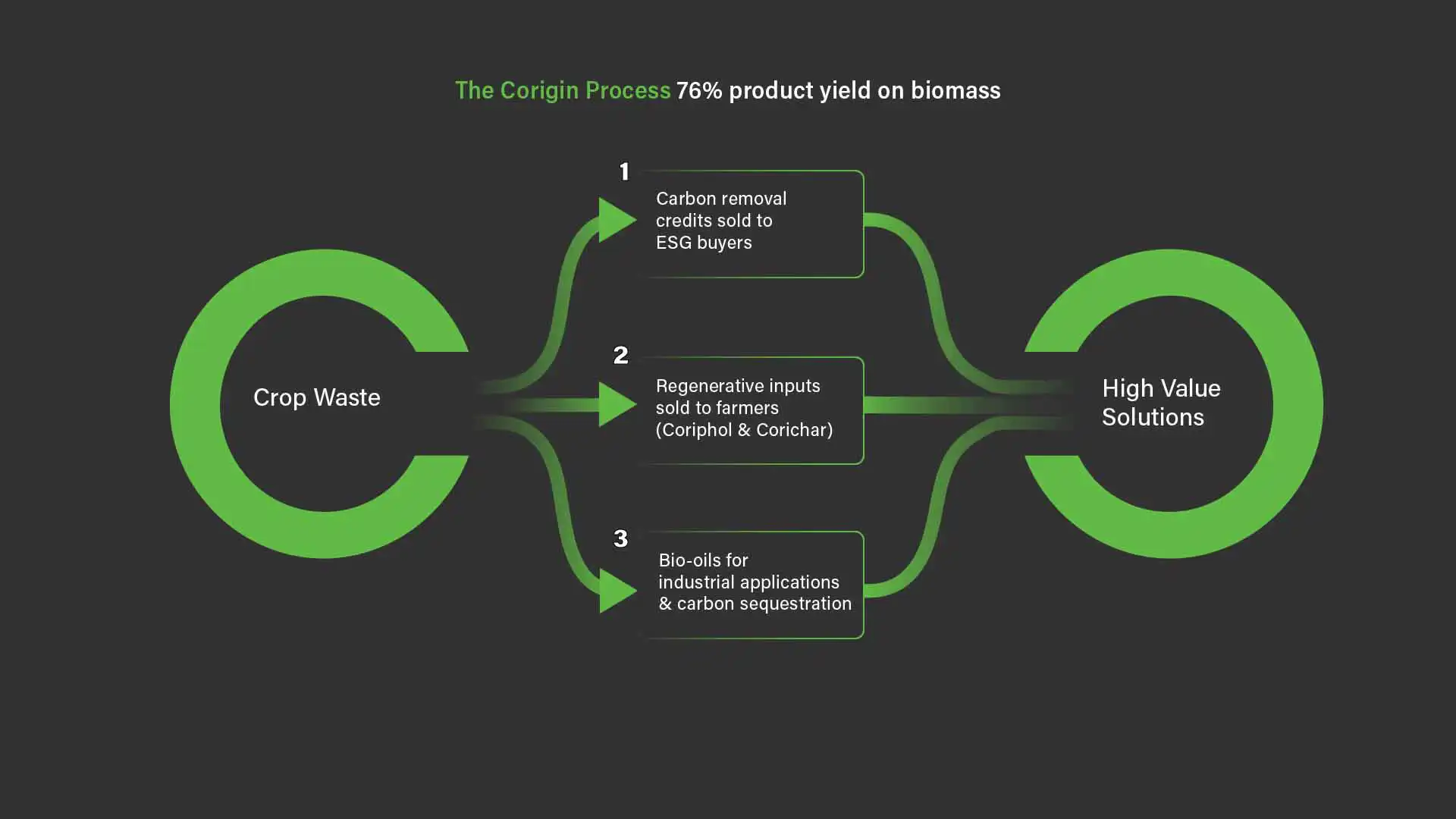

Taking agricultural waste and turning it into multiple products that help the earth, farmers and make money.

Our Carbon Removals Provide Multiple Co-Benefits Beyond Carbon Removal

| How Much Co-linear Value Is Really Produced by Carbon Removal Platforms? | Skilled Jobs | Biodiversity | Water Security | Soil Security | Circular Economy | Displace Synthetic Chemicals | High Profit Potential |

|---|---|---|---|---|---|---|---|

| Corigin: High Margin Products Sold to Farmers & Industry | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Reforestation | Yes | Yes | Yes | ||||

| Direct Air Capture Machines - Pump CO2 Underground | Yes | ||||||

| Limestone Mineralization – Pump CO2 Underground | Yes | ||||||

| Bio-Oil Sequestration – Pump Oil Underground | Yes | ||||||

| Bioenergy Carbon Capture & Storage - Biomass to Energy & Pump CO2 Underground | Yes |

-

No Technology Risk or Regulatory Risk

-

No Technology Risk or Regulatory Risk

-

We’re Ready To Go Now!

Carbon is Removed from the Atmosphere & Credits Sold. Products That Don't Decompose:

-

Increase Crop Yields

-

Regenerate Soils

-

Reduce Fertilizer Use & N20 Emissions

-

Reduce Methane Emissions

-

Reduce Demand for Synthetic Chemicals

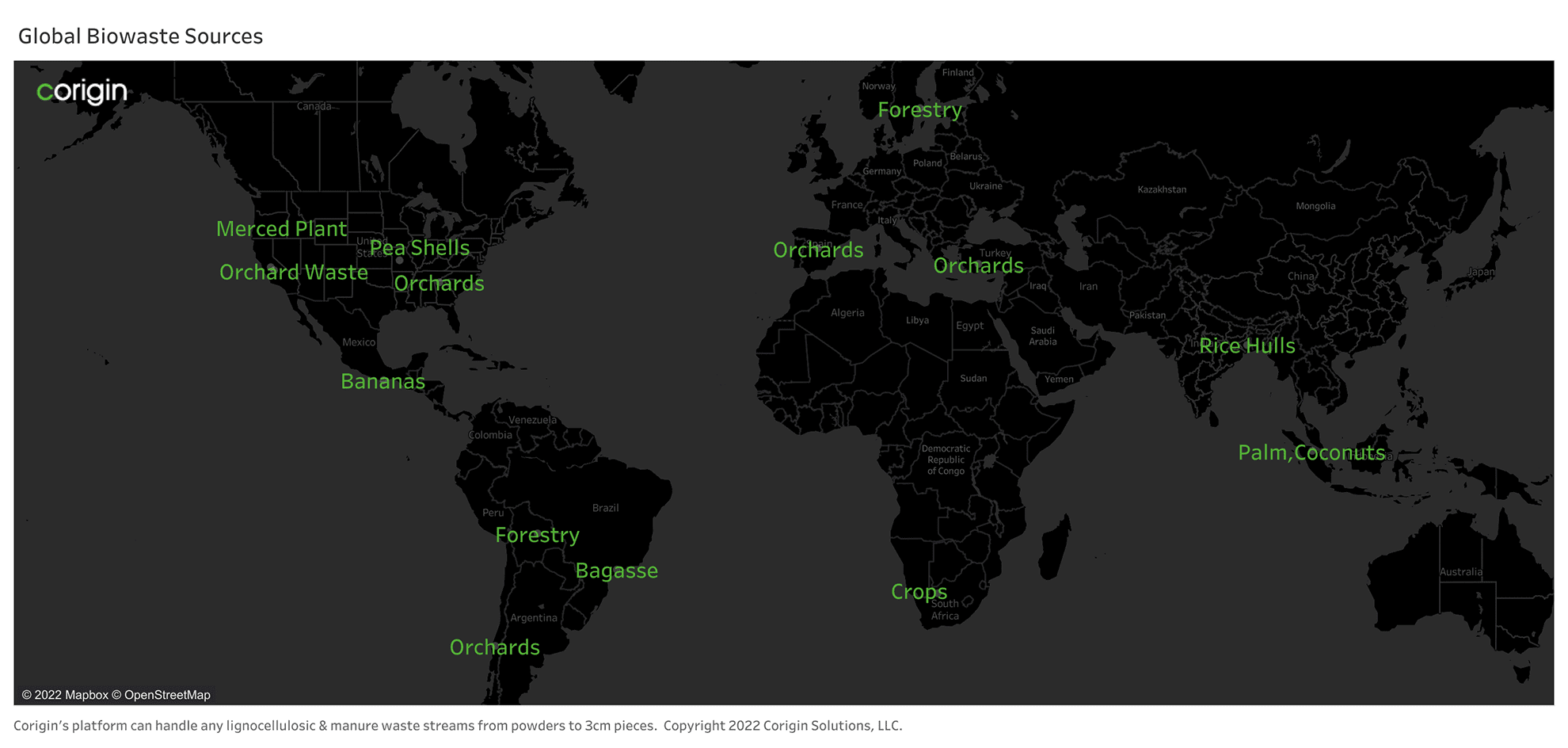

Strategy to Scale We'll Build Many Corigin Plants Around the World Because the World Needs It!

Farming is the most widespread economic activity on Earth. Every farming community in the world could have access to a Corigin plant from Indonesia to Zambia, converting their crop wastes into regenerative products that permanently sequesters carbon and displaces fossil fuel derived fertilizers and chemicals.

Corigin Solutions

Equity in parent, funds plant 1

Plant 1

Equity financed

Plant 5

Non-dilutive capital used to scale – build replicate plants

Plant 10

Replicated plant

Plant 20

Replicated plant

Manufacturing & Biorefinery Technology Platform

-

First Plant

Online, processing ½ ton biomass/hour continuous in Merced, CA.

-

Capacity

Standardizing on 2-ton biomass/hour for additional production capacity & streamlined fab. Scalable to 10- tons continuous throughout.

-

Based on (A) molten salt heated reactor under vacuum that minimizes thermal gradients and assures process consistency and (B) proprietary biorefinery module to produce high-value distillates.

Sophisticated GUI software for remote monitoring & continuous process control.

-

Feedstock Agnostic

Perfect for crop, forestry & manure waste processing the world over.

Read More

All of the carbon in our products was in the atmosphere a few months ago.

Most of it is never going back. Let’s grow together!

Seen here... 14 cubic meters of Corichar shipping to a customer for carbon sequestration.